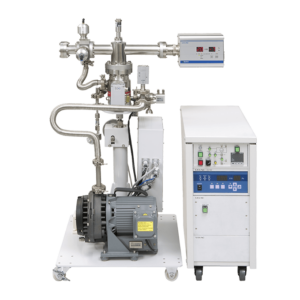

This process monitoring system has been developed for various kinds of applications such as etch, CVD and other reactive gas processes.

Using ULVAC's original ion source and pumping system enables you to achieve stable measurements results.

Using ULVAC's original ion source and pumping system enables you to achieve stable measurements results.

Features

- Long term stable measurements results

- Communication interface Ethernet compatible

- Closed Ion Source Utilizing a Magnetic Field:

Soft ionization provides less gas dissociation and higher sensitivity. Decomposition and adsorption due to thermal reactions are minimized in the ionization chamber. - Short distance between the process chamber and ion source allows quick-response of analysis.

- Wide pressure range from 10-6 to 13kPa is available. (Choice of orifices)

- No need for PC

- "One Click" function

- Max 120℃(248℉) High temperature bakeing.

- Electron bombard degas

- Protection and maintenance of ion source and secondary electron multiplier

- Traceability of analysis tube (patent pending)

- Various Leak Tests are Available (Helium leak test, air leak test, leak up)

- Capable of total pressure measurement (External ionization gauge GI-M2)

- This software is included and compatible with (Windows 7/8/10)

Applications

- For etching and CVD process

- Monitoring reactive gases during process

- End-point monitoring for etching and cleaning processes

- Residual gas analyzing

- Leak testing

Specifications

| Model | RGM2-202 | RGM2-302 |

| Sensor | ||

| Mass filter type | Quadrupole | |

| Mass range | 1 to 200 amu | 1 to 300 amu |

| Resolution | M/△M=1M (10%P.H.) | |

| Detector type | SEM/Faraday cup | |

| Sensitivity | 1×10-3 A/Pa | |

| 1.33×10⁻¹ Torr | ||

| 0.1A/mbar | ||

| minimum detectable partial pressure

(inside analyzer tube) |

1×10-10 Pa | |

| 7.5×10-13 Torr | ||

| 1×10-12 mbar | ||

| Ion source | Closed ion source utilizing a magnetic field | |

| Filament | Ir/Y2O₃ coated V type, 1pc | |

| Ionization voltage | 20 to 70 eV | |

| Emission current | 10μA | |

| DC amplification range | 1×10-5 to 1×10-12 A | |

| Maximum bakeout operating temperature | 120℃ (248℉) | |

| Differential pumping system | ||

| Gas inlet value | Conductance value with 3 different gas inlet modes (VPC-070) | |

| Max. sampling pressure | 13kPa | |

| 97.5Torr | ||

| 130mbar | ||

| Differential pumping system | With intermadiate port and gas purge port | |

| Turbo molecular pump | 67L/s:N₂ | |

| Fore pump | DIS090 | |

| Pirani vacuum gauge | SW1-1 | |

| Ionization vacuum gauge | GI-M2 | |

| Weight | Pumping system:57kg / Controller:38kg | |

| Utility | ||

| Power supply | AC100V 15A | |

| Compressed air | Dry N2:0.4 to 0.7MPa (Φ6 one-touch joint) | |

| Dry N2:3×10⁺³ to 5.25×10⁺³ Torr (Φ6 one-touch joint) | ||

| Dry N2:4 to 7 mbar (Φ6 one-touch joint) | ||

| Control unit | ||

| "One Click" function | Capable / He/H2O/N2/O2/Any gas | |

| External I/O and other | Analog input×2 (0 to 10V) | |

| Set-point output×2 (fault,alarm) | ||

| External interlock | ||

| Others | ||

| Baking heater | Tape heater | |

| Stand | Standard | |

| Sensor unit (Control box cable) | 5m | |

| Interface | Ethernet | |

| Software | Qulee QCS Ver.4.0 later(Windows 7/8/10) | |

| Option | PC | |