Vacuum Cooling System

Home » Product » Vacuum Equipment » Vacuum Cooling System

The application of vacuum cooling technology has caused a revolution in the green vegetables cold chain distribution system. In summer time, vegetables tend to deteriorate very fast after harvest from the field under high temperature.

Principle of vacuum cooling

It is therefore, necessary to cool the vegetables down to about 0°C within a short time to preserve its freshness.The most effective method to cool down vegetables is under vacuum through self-evaporation of water.The “main principle is when a vacuum chamber is filled with green vegetables and evacuated, the free water in the cell tissues of the vegetables begins to evaporate at a pressure and the vegetables cool themselves due to the latent heat of the evaporating water.Since 597 Cal is required to vaporize 1 gram of water at 0°C, the vegetables are cooled to 0°C in about 20-30 minutes when the chamber is maintained ~t a pressure of about 4.6 Torr. The large amount of water vapor generated inside the chamber is condensed on the surface of the cold trap and removed from the chamber. The system uses a refrigerator to keep the cold trap at a low temperature.

Advantage of Vacuum Cooling

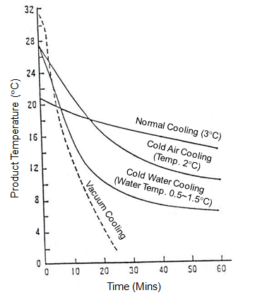

- Cooling time is very short, usually only 20-30 minutes.Therefore, it can take away the heat including field heat and respiration heat from the post-harvest vegetables in the first time, this heat is deadly to keeping the freshness

- Cooling is very uniform.Vacuum cooling assures uniform cooling.There is no temperature difference between the leaves and the stalk core. Freshness and cleanliness are essential features of vacuum processing.

- After being vacuum cooled, vegetables have excellent freshness, color, flavor and nutritional components, and can be stored for a long time.

- The vacuum cooling technique is beneficial for removal of harmful gases and killing pests so as to increase the shelf-life period of vegetables.

- Can deliver/export to distant countries under cooling

- No restriction to harvest.Green vegetables can be picked at any time,since they can be cooled in only 20-30 minutes.

- Optimization of yield.Since only about 2-3% of the water is vaporised,there is no danger of the vegetables drying out or their weight being reduced.

- Harvesting in the rain is possible.The water clinging to the surfaces of the vegetables is moved in a vacuum, and there is no damage during transportation.Even some vegetables washed in water can be processed.

- Can be cooled in the package. The vegetables are delivered in a clean package, maintaining their original freshness and texture.There is no distransportation. Evenr changes.

- Can do spray or sterilised treatment inside vacuum chamber.