Vacuum Distillation System ,Permitting distillation of highly heat-sensitive material (thermally decomposing / polymerizing substances) under vacuum at a low temperature and within a short time.

Features

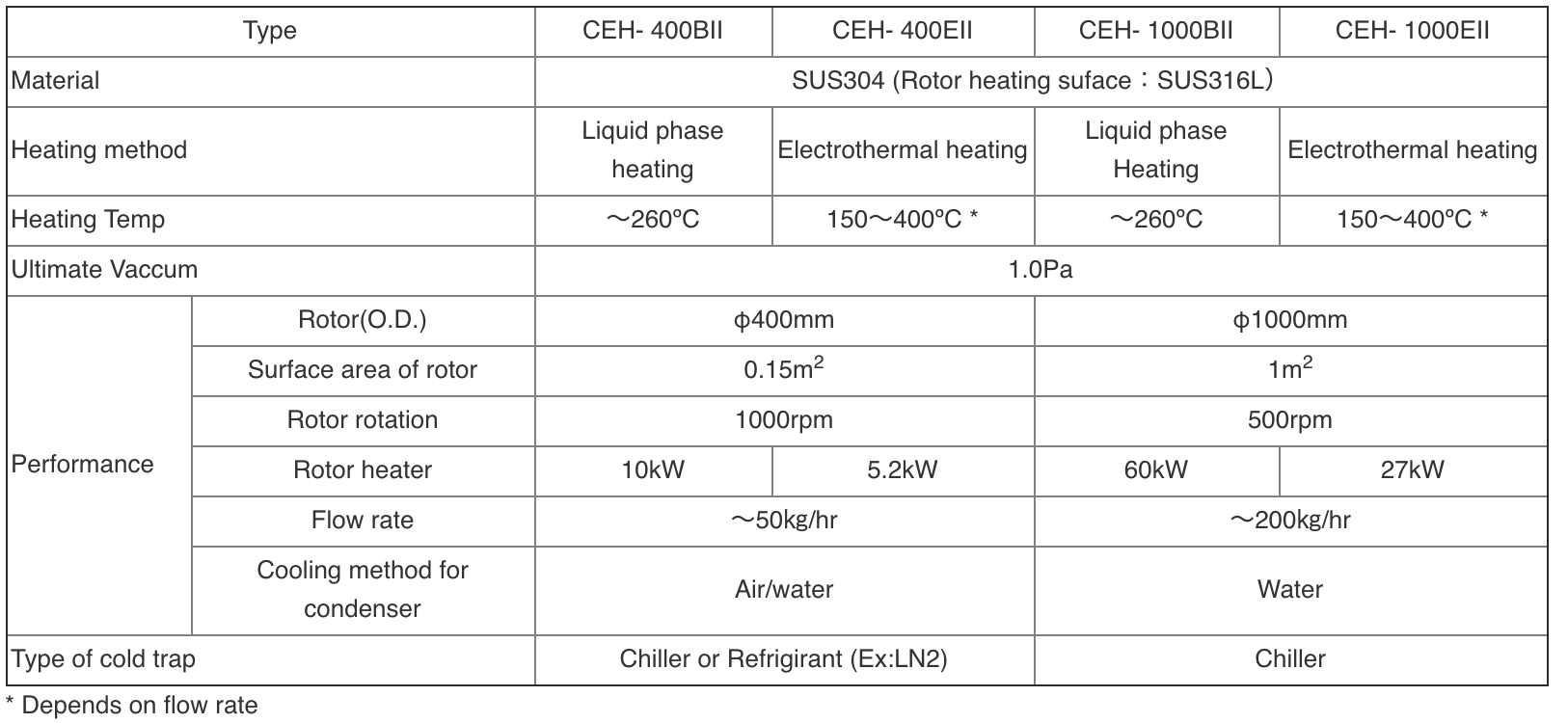

- Either of two heating systems can be selected as needed : Indirect heating by a heating medium (CEH-B) or radiant heating by an electric heater (CEH-E).

- Centrifugal force created by a rotor rotating at high speed on the evaporation surface creates thin, uniform evaporation films.

- Processing can be performed instantaneously at relatively low temperature in a high vacuum, minimizing quality deterioration due to heat.

- Models with a circulated heating medium system enable user-set temperatures and highly precise temperature control. Explosion-proof models are available, for processing materials containing solvents.

- The wide range of supported applications includes concentrating, deodorizing, degassing, solvent removal and desiccating.

Applications

- High vacuum distillation for various vitamin, DHA, EPA, squalene, oil and fats.

- Refinery for vacuum pump oil, chiller oil and transformer oil.

- Fillers for electronics and semiconductors, vacuum heat treatment for mold materials.

- Refinery for fatty acid amides and other fatty acids.

Specifications