ULVAC’s base technology with vacuum technology at its core and related peripheral technologies have been combined through many years of R&D and improvements in manufacturing technology, enabling us now to deliver a very wide range of industrial manufacturing equipment for semiconductors, electronic parts, FPD, solar cells, and others.

Helium Leak Test System

ULVAC is the worldwide leader in Automatic Leak Testing solutions for manufacturing operations in Air Conditioning, Refrigeration, Automotive.

Vacuum Evaporation System

This equipment, employing vertical double door open mechanism is applied to deposit Al reflection film and superposition SIOx protection film on the reflection board of automotive lighting parts and decoration. Perform film metallization on the PC,BMC,ABS metal materials.

Vacuum Roll Coating System

EWA is by far the oldest, most mature ans most widely used introduction heating evaporation coating equipment under the ULVAC Technical.

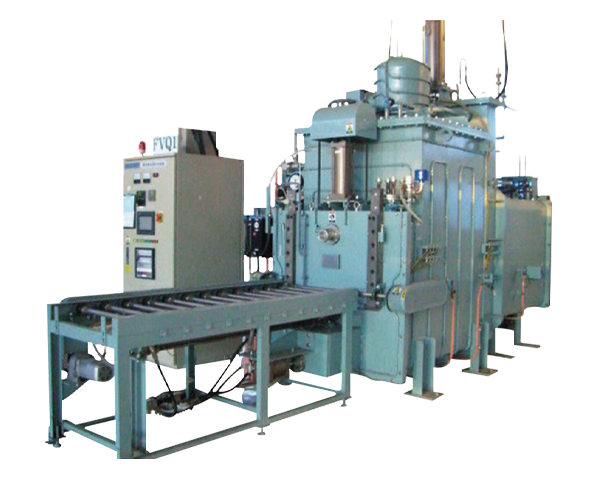

Vacuum Furnaces System

ULVAC offers vacuum furnaces (for melting, thermal treatment, and CVD) used in general industrial fields and semiconductor/electronic device fields.

Vacuum Cooling System

The application of vacuum cooling technology has caused a revolution in the green vegetables cold chain distribution system. In summer time, vegetables tend to deteriorate very fast after harvest from the field under high temperature.

Refrigerant Charging Machine

Charging Machine is a perfect solution for high for high accuracy and fast speed charging,integrating multiple advantaged and advanced technology.

Vacuum Distillation System

Vacuum Distillation System ,Permitting distillation of highly heat-sensitive material (thermally decomposing / polymerizing substances) under vacuum at a low temperature and within a short time.

Vacuum Freeze Dry System

Vacuum Freeze Drying / Vacuum Drying System for low-volume production and research by the pharmaceutical industry require space-saving designs, low cost and high functionality. ULVAC has released the DFM Series to meet these demands.